At Atelier Noterman, we believe in a step-by-step approach. We want to carefully evaluate what is technically and economically feasible. That is why we set realistic goals. For us, honesty and transparency are at the heart of a sustainable future.

Transparency

Transparency is the basis for a more sustainable future, and we want to set an example in this. That is why we take it for granted to be open about our suppliers. We choose our partners with care, based on their quality, reliability and commitment to sustainability. Here is an overview of our suppliers and why we chose them:

Fabrics

Olimpias Group S.r.l., Italy

A renowned textile manufacturer with a strong focus on sustainability and innovation.

Nuova Tessilbrenta, Italy

Although Nuova Tessilbrenta does not yet fully meet our sustainability expectations, we work together because of their wide and diverse range of fabrics. This collaboration allows us to continue to innovate and inspire our partners to take more sustainable steps.

Candiani Denim, Italy

Known as one of the most sustainable denim manufacturers in the world, thanks to their innovative and environmentally conscious production processes.

Cervetessile

We partner with Cervotessile because of their commitment to quality and sustainability.

Labels

Cadicagroup Spa, Italië

This company has a strong focus on using recycled materials.

Passamar, Portugal

We choose Passamar because of its short distance from the ready-to-wear atelier Green Dolphin, with which we are looking at a small footprint and supporting the local European economy.

Buttons

We still check the sustainability reports of our partners, such as Knopf & Knopf (Germany) and Louropel (Portugal), to keep improving our impact.

Knopf & Knopf, Germany

Louropel, Portugal

Laundries

IVN Laundry, Portugal

Innovative Eco Wash processes are used at IVN Laundry in Portugal, with a focus on water conservation and environmentally friendly techniques.

Pizarro S.A., Portugal

Known as one of the most sustainable denim manufacturers in the world, thanks to their innovative and environmentally conscious production processes.

Production

Packaging

Logistics

TN – Transportes Nogueira, Portugal

Portugal > Belgium

We choose TN - Transportes Nogueira in Portugal because of their reliability, efficient logistics solutions and focus on sustainability within transport.

Bleckmann

ATN customers/delivery retail

FedEx Express

ATN customers/delivery retail

Ingredients

Honesty

Honesty is a fundamental value at Atelier Noterman. We believe it is important to be open and clear about the way we work and the choices we make. By integrating honesty into every aspect of our work, we aim to build trust and make a positive impact on people and the environment. For us, honesty is not just a principle, but a daily practice.

People

At Atelier Noterman, we believe that our people are the beating heart of our business. We treat our employees with respect because they are capital to our success.

Team Belgium

Portugal, Green Dolphin

Environment

Production process, raw denim*

Less water, less toxics, less energy

Indigo, the distinctive colour of denim, causes significant environmental impact through dyeing. This process uses polyvinyl alcohol (PVA), a toxic chemical that can only be removed with intensive rinses, requiring up to 300 litres of clean water per kilo of fabric. Detox Denim offers a more sustainable alternative by replacing PVA with Chitosan, a 100% natural and biodegradable substance derived from crustaceans. This innovation not only lowers water consumption and pollution, but also reduces energy consumption during production.

In addition, alternative ecological processes have been developed to wash denim cleaner. Technologies such as ozone washing and laser processing make it possible to treat denim without using large amounts of water and chemicals. Atelier Noterman is one of the brands using such ecological alternatives, contributing to a more sustainable and eco-friendly fashion industry.

Washing process after confection

Our Detox Denim is washed (almost) without chemicals and almost without water. We use the Ozone technique through our Pizarro laundry: this is the imitation of sunlight to give jeans their unique ‘washed’ look.

*Raw denim(also called dry denim) refers to denim that is unwashed after dyeing, not necessarily after weaving. The distinction lies in the fact that the fabric is dyed after the weaving process, often with indigo, but is not washed or treated to make it softer or less stiff. This leaves the fabric in its raw, pure state.

Sustainable profit

Atelier Noterman also takes responsibility in Portugal. Our partners ensure fair wages and contribute to good working conditions wherever we operate in the world.

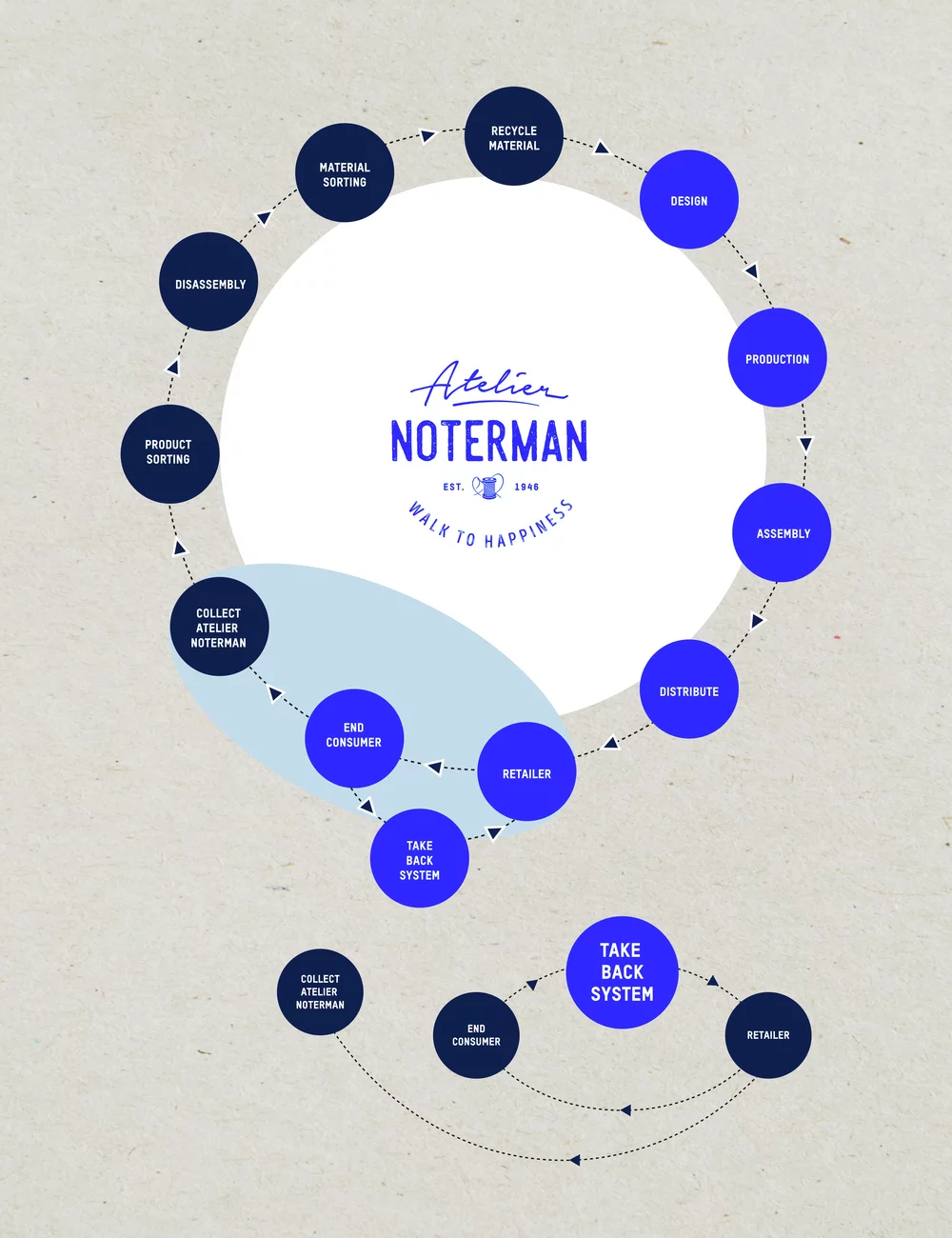

Circular

Sustainability is central to our way of working. From carefully selecting high-quality, durable materials to designing products that last longer. Our ambition is to minimize waste and maximize the reuse of products and materials. We contribute to a fashion industry that remains innovative in design, materials, and colors while also taking responsibility. A (fashion) world where sustainability and quality go hand in hand.

Design

At Atelier Noterman, everything starts with a timeless design, developed in our offices in Kluisbergen. Our fits evolve gradually, ensuring that our trousers can be worn for many years without going out of style.

Production

Our production takes place in northern Portugal, in the province of Braga, while our points of sale are in Belgium and the Netherlands. Thanks to this local production and fabrics mainly sourced from Italy, we keep CO2 emissions from transport low.

Assembly

Our trousers are not only made from high-quality fabrics but are also reinforced where necessary to guarantee a long lifespan.

Distribution

Our customers are in Belgium and the Netherlands, and with production in northern Portugal, our trousers do not travel long distances. Transportes Nogueira (Portugal-Belgium transport in boxes), UPS, and Bleckmann (distribution to Belgian and Dutch stores) are reliable partners investing in the sustainability of their freight and delivery vehicles.

Retailers

We encourage our retailers to actively promote our vision of quality and sustainability.

End Consumer

Atelier Noterman makes trousers that are strong and timeless, allowing them to be worn for many seasons.

Système bring back

Consumers receive a €10 voucher for each returned pair of trousers. This voucher can be used for the purchase of a new pair and is valid until December 31, 2025. Vouchers will be issued until June 1, 2025, after which all trousers will be collected.

Product Sorting

The Bring Back Action is a test to determine how many and what types of trousers are returned, including chinos and denim, and in what condition. We are researching the potential for second-hand resale, repairs, or, if not possible, recycling.

Disassembly

At the end of a trouser's life (when repair or second-hand use is no longer possible), is mechanical rather than manual disassembly feasible? This depends on technological innovations beyond our reach. Just as sewing machines exist to stitch clothing parts together, machines/robots will need to be developed to "unstitch" clothing components.

Material Sorting

After disassembly, the various materials must be sent to specific processing companies (fabric, buttons, zippers, labels, etc.).

Recycle Material

We closely monitor what happens to these dismantled components and whether they can be reused specifically for our trousers or in entirely different applications.

As a first step in the circular economy, Atelier Noterman is launching the Birng Back System from January 2025. Atelier Noterman wants to learn how the market reacts and what motivates end consumers to participate in sustainability and circularity. Atelier Noterman is keen to learn from the state and number of returned trousers.

You are important to us! As this diagram shows, we can only move towards a circular economy if YOU participate too! Without you no returned trousers, without your cooperation our trousers remain waste. And we want to counteract that.

We have set up a pilot with the shops below. In other words, you can bring in your discarded Atelier Noterman trousers and in exchange you will receive a €10 voucher. You can use this voucher for your next purchase of Atelier Noterman trousers.

Summary

Transparent communication is the first requirement for a sustainable, fair, and circular economy. Atelier Noterman is taking the lead in this. Sustainability is an all-encompassing story of people and the environment. We prioritize people first, followed by nature, the environment, and the climate. What do we mean by that? Treating people with respect is a given, and that also means fair wages. A pat on the back is certainly nice and necessary in a work environment, but bills ultimately need to be paid. A good wage is more than a subsistence wage—it should cover more than just basic needs and also allow for some leisure activities.

That is why we have published the wages of the Portuguese employees (seamstresses and staff) of Green Dolphin on our website. Green Dolphin is the workshop where almost all Atelier Noterman trousers are made. This is not our own workshop, and these seamstresses are not on our payroll, but we choose to work with a workshop where we are 100% sure that the working conditions and wages are fair. And at Green Dolphin, they absolutely are! We have a very personal relationship with the owner, Miguel Fonseca, and we know that he upholds the same values in business and life.

A crucial aspect of this approach is that when people are paid fairly, they have the ability to consider more "climate-friendly" products. A subsistence wage means that when purchasing a product, the origin and impact of that product cannot be considered—only the price matters.

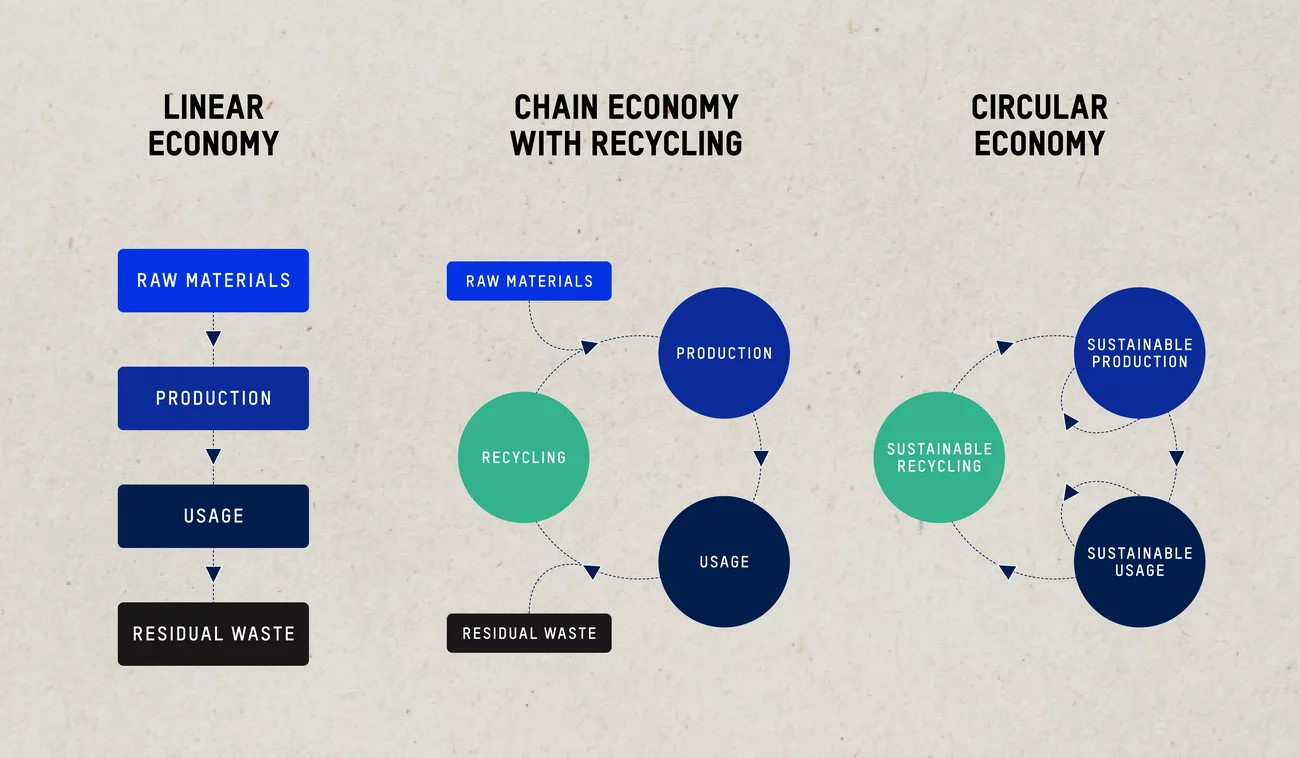

Ongoing climate change makes it clear that the industry must change. The linear economy, which relies on fossil fuels, is ultimately detrimental to nature, the environment, and the climate. By continuously using new raw materials, we deplete our resources and reduce biodiversity. Extracting raw materials also involves environmentally harmful (use of chemicals) and socially unjust (unacceptable working conditions) practices and requires large amounts of energy, whether renewable or not.

The fewer harmful techniques we use and the more renewable energy we rely on, the better. In fact, eliminating harmful techniques altogether should be the goal! Atelier Noterman recognizes that we must reuse raw materials, avoid chemicals, and eliminate CO2 emissions. We are far from achieving this.

What are our main focus areas?

We purchase environmentally friendly fabrics and accessories, such as denim from Candiani and recycled polyester labels. Our jeans are washed using ozone technology (simulating sunlight), which significantly reduces chemicals and water consumption (see list published on our website). By sourcing primarily European fabrics and accessories, producing in Portugal, and selling our trousers mainly in Belgium and the Netherlands, we keep transport emissions as low as possible.

Circularity remains the biggest challenge.

See: Bring Back Action – product sorting – disassembly – material sorting – recycled material.

Can we adapt our design to make trousers easier to dismantle? Can we use materials that are easier to reuse?

At this moment, it is difficult to predict what future industrial-scale technologies will allow. Current developments are mostly (subsidized) pilot projects on a laboratory or small scale, primarily driven by major fashion brands. We are a small player who cannot set the rules; we must follow what becomes technically feasible. However, we will be among the first to implement viable circular solutions.

What can we improve in the short term?

Monitor fabric waste and involve our Portuguese partner in our circularity efforts. Limit surplus fabric and accessories. Be more conscious with leftovers—avoid resellers, donate to charity, or sell at reasonable prices. Create a project around second-choice trousers, enhancing their value through high-quality repairs, with part of the proceeds going to charity.

Below is a representation of a circular economy. If everyone in our sector is honest, we acknowledge that we are still far from achieving this. In my opinion, the fashion industry must abandon the idea that 100% circularity is achievable in the near future (10-20 years). Why? Because 100% circularity means that every button, zipper, thread, woven label, hangtag, fabric piece, lining, and all "new" garments made from old ones must be reintegrated into the supply chain without incineration. Circularity currently focuses primarily on mono-materials, while most fashion items are made from mixed materials.

At this stage, aiming for 100% circularity ignores economic realities. Atelier Noterman is ambitious on all fronts, but we also want to be realistic and honest.